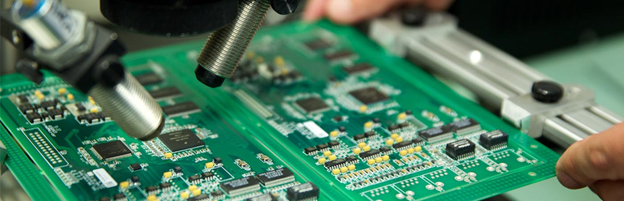

The purpose of this test is to determine the ability of the product to withstand the effects (material fatigue, temperature stresses etc…) of fast changes of temperatures from 85°C to -40°C

This test put a strain on product so that the subsequent effect of different coefficients of thermal expansion of parts of the product is show up hidden defects like poor soldering, cracked cells, delamination, performance reduction and inuslation resistance etc.).

It maintains the required temperature without any problems by cooling units and ventilation systems, which allows to pressurize the unit under test according to the values measured in the air. This ensures proper pressure screening and avoids large differences between the temperatures measured in the air and the sample, which would render the test ineffective.

ESS was developed to help manufacturers detect product defects and manufacturing defects. Screening can force infancy board and component failures that may occur after final assembly and product delivery

It aims to eliminate all types of defects, avoid material damageand increase reliability. ESS improves product quality, product reliability, production efficiency and profit margins. It reduces field defects, time to market and failures in the field.